The Problem

2020 studies have shown that aerosolised sub 5 micron COVID -19 particles spread and remain suspended in the air for up to 3 hours in non-ventilated and poorly ventilated spaces.

In addition, many hospital procedure rooms including ICU and theatres are normally positive pressure spaces designed to protect the patient from infection. Some older cohort wards are not ventilated at all. This allows the virus to concentrate and spread.

Bio-safety experts consider face masks worn by frontline staff do not offer full protection against sub 5 micron virus particles.

Higher air effective change rates are known to dilute the aerosolised viral loading but this does not always work as zonal stagnation of air is a common problem.

An interesting article about to be published in July 2020 in CDC is starting to address the matter see:- https://wwwnc.cdc.gov/eid/article/26/7/20-0885_article

Virus scrubbing units have been adopted by a number of NHS trusts:- Treliske Hospital Cornwall UK already have 8 units delivered as of 1st April 2020. The idea has now been adopted by Exeter RD&E and is being trialled at the Royal Berkshire hospital.

The solution

Healthcare staff, including those required to undertake close proximity care such as dentists and nurses can be better protected using 4 additional techniques:-

1) Virus Capture Aerosolised Covid-19 droplets are reduced by capturing virus at source or adjacent to the infected patient.

2) Directed air flow:- Large parts of the clinical space will be protected from the accumulation of virus by displacement (or shunt) ventilation. Here air is now moved away from medical staff past the patient. As the air moves directionally, the aerosolised virus is entrained, sucked away and filtered out.

3) Dilution:- The virus concentration can build up such that sufficient virus will result in an infectious dose. By providing a good air change rate within the space, the air is diluted such that after say 5 minutes after virus is present the air is clear.

2) Negative pressure:- The scrubber device can easily be set up to keep infectious spaces under negative pressure thus stopping contaminated air from escaping to other parts of the building.

To comply with the above objectives we have designed and manufactured a series of simple combined virus scrubbing modules using a very fine HEPA14 (ASHRAE MERV14 or 19) to catch and kill the virus. The design can also be used to keep the containment space under negative pressure.

We can in addition to HEPA filtration incorporate a powerful UVC light source to kill airborne virus.

The filter and super quiet fan are connected to lightweight flexible air ducts which can be quickly installed. The ducts will extract aerosolised virus from behind the patient.

Clean scrubbed air is reintroduced into space.

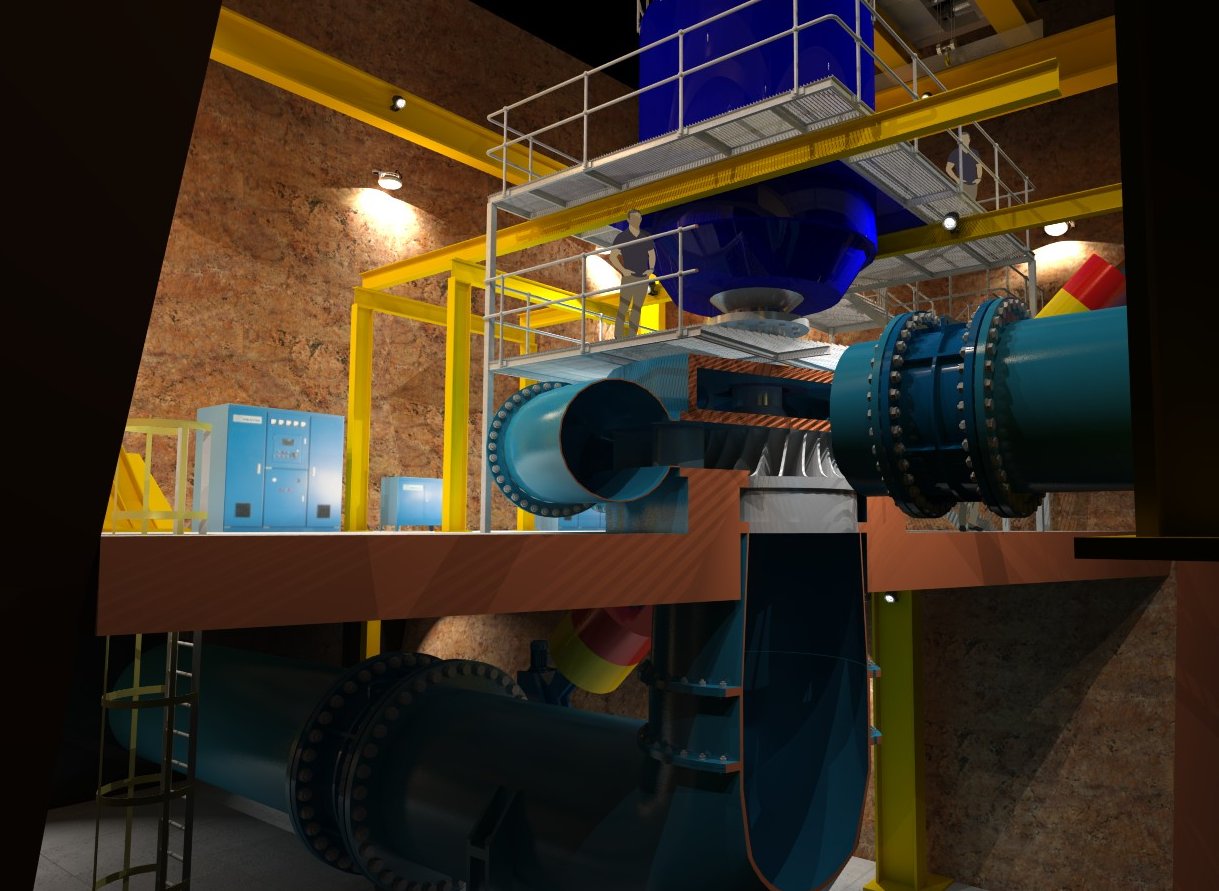

Ward and waiting room units

Fig 1 – Hospital ward application.

These larger scrubbing units filter up to 300 litres per second and are useful for spaces where it is know that there is a higher risk of aerosolise virus being present. A variety of ducted systems can be designed as either temporary or permanent features of the space.

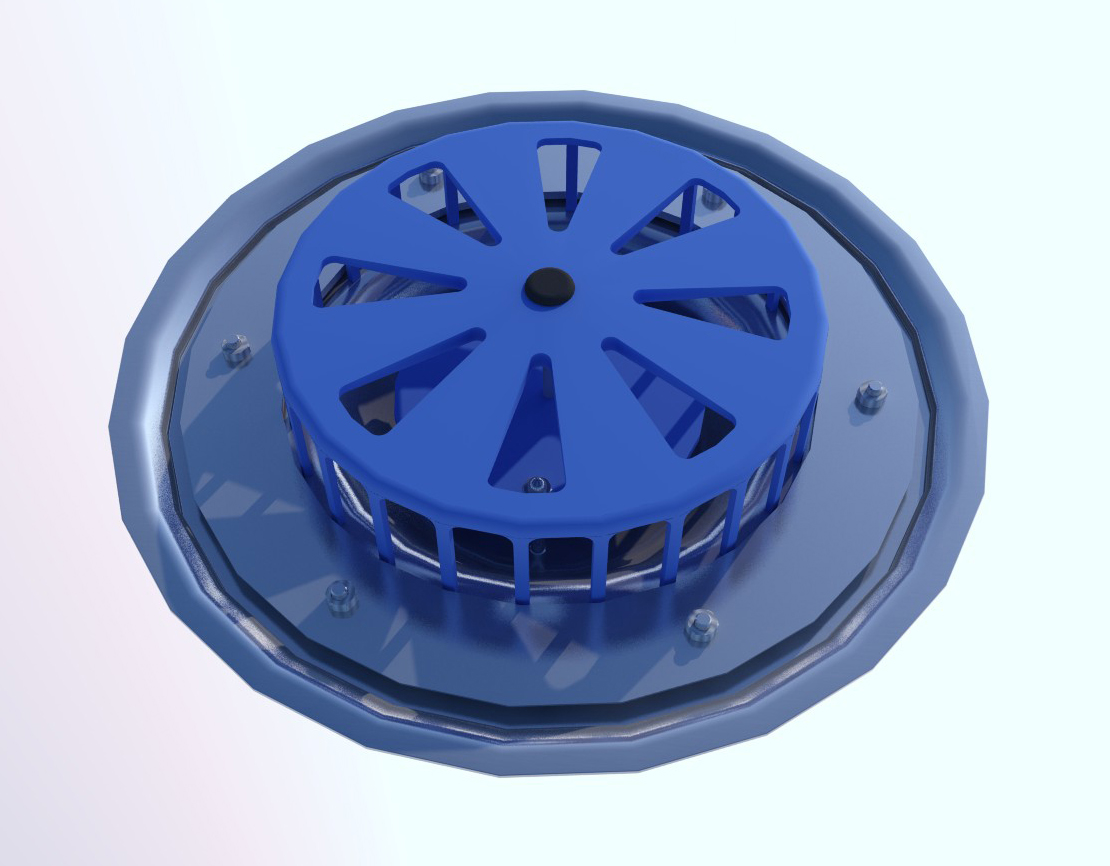

Dentist rooms

Fig 2 – dental room application.

Here a bell-mouth air intake, extracting up to 200 litres per second, is positioned adjacent to the patient. Any virus expelled is immediately sucked into the HEPA filter and captured. The time allowed to clear the air between patients would be in the order of 5 to 8 minutes.

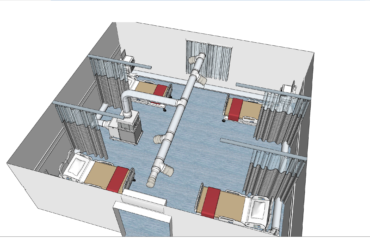

Consulting rooms

Fig 3 – consulting room application.

By extracting the air, up to 200 litres per second, adjacent to the patient, any aerosolised pathogens present would be immediately captured in the filter. This cleaned air would be reintroduced on the other side of the consulting room adjacent to the clinician. The time allowed to clear the air between patients would be in the order of 5 to 8 minutes. Waiting times between patients would be reduced from an hour to about 5 minutes.

In addition, the carbon filter located inside the scrubber will immediately remove any unpleasant order from the room.

The Units can also be fitted with ultra violet (UV) lighting tubes which will efficiently kill all bacteria and virus pathogens in the air. This is an optional feature which can be applied to all units mentioned above.

Each unit comes with the following features:

- Fan speed controller.

- An F7 pre-filter which ensures the HEPA filter has longevity

- An on off switch

- A indicator dial to notify when filter need changing

- A control panel to allow you to switch the UV lights on and off as required

- Zinc galvanised Internal surfaces, which creates a excellent biocidal surface.

- Wheeled casters with individual wheel locks for safety.

- Acoustic lining to attenuate noise

(All units are professionally painted to allow for cleaning in a medical environment)

Availability

Scrubbing units are built to order. For the best results approximate dimensions or a photo of the room should be provided to optimise the room layout and the position of the ventilator. Permanent solutions include the use of the space above the suspended ceiling to allow flexible ducts to be hidden.

We will advise on the duty required and price for the correct solution including additional UV sterilisation and ductwork components.