Posted on April 27, 2018 by Focus Technology -

GPJ Consulting Engineers were employed by the Retallack Resort to carry out a survey and re-design of the ride’s protective safety cushions.

The artificial surfing wave ride was installed approximately 6 years ago and after many years of heavy use has seen the protective foam crash pads and vinyl outer covering wear out.

GPJ Consulting Engineers visited site and took accurate dimensions of the existing installation. These were transferred to a 3d model which enabled us to design a cutting plan to allow a local contractor to fabricate the foam pads and vinyl covers.

Stainless Steel reinforcement of part of the ride was also undertaken to further extend its useful life.

Posted on April 27, 2018 by Focus Technology -

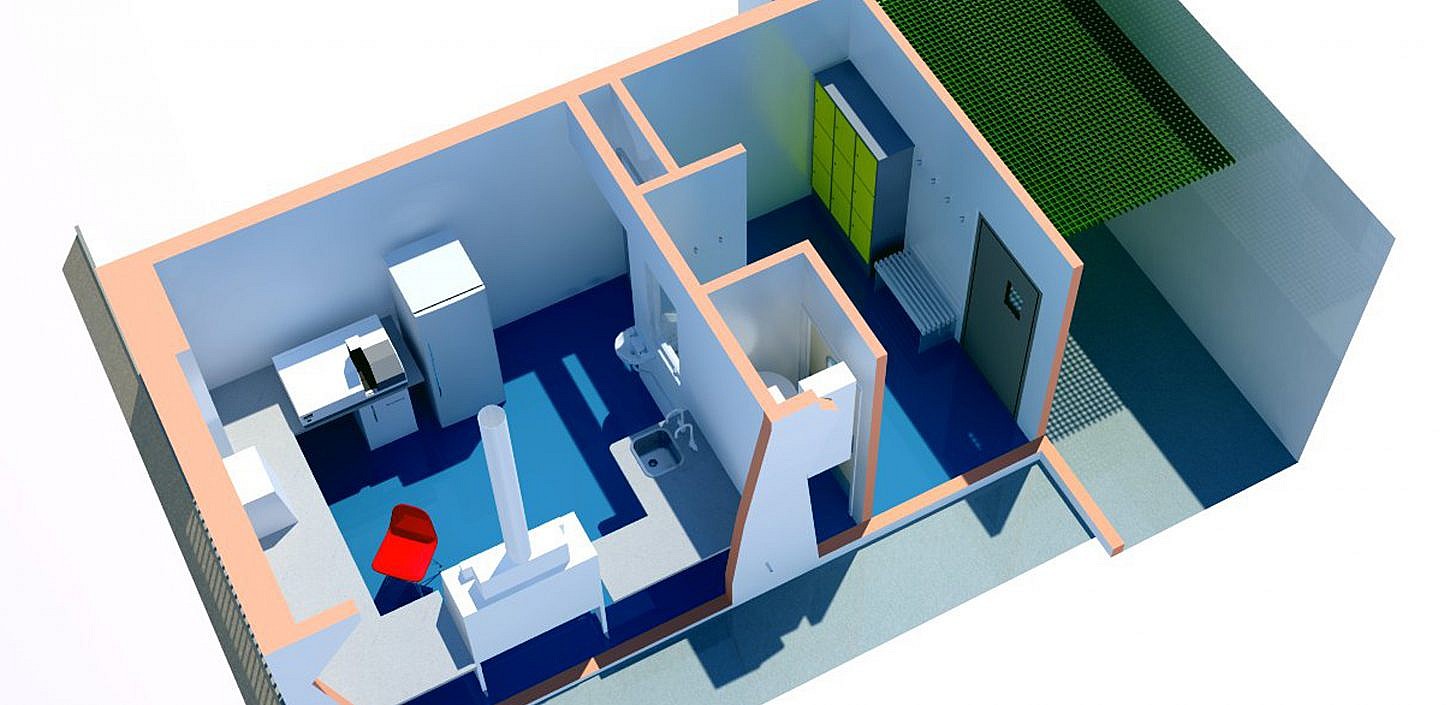

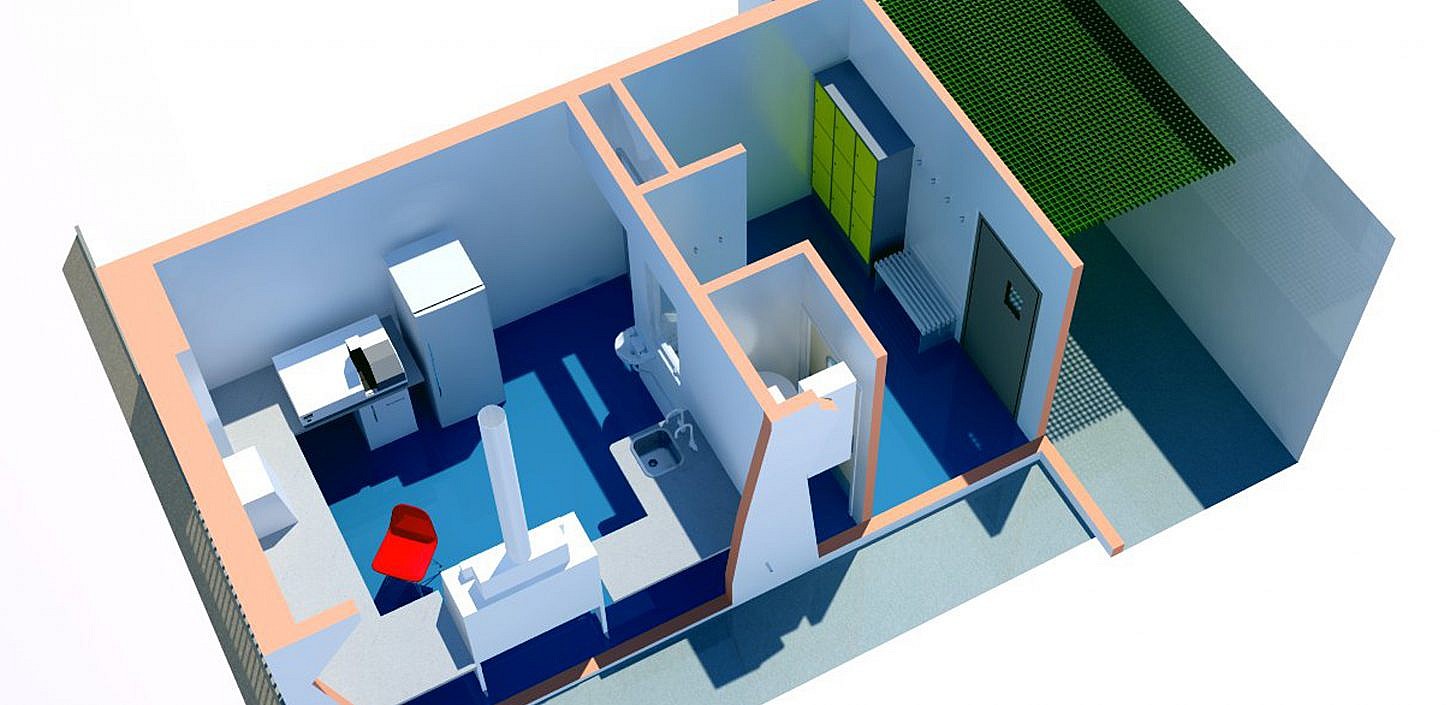

Lister School is a recent new build complex in Newham, London.

GPJ Consulting Engineers have successfully designed the remodelling of the classrooms from a general purpose room to a new science lab and adjoining meeting room. All of the existing services were adapted to suit with new electrical, drainage, heating, domestic plumbing and ventilation services modified.

Posted on April 27, 2018 by Focus Technology -

GPJ Consulting Engineers are employed by local school’s and their facilities management companies to survey, design and project manage mechanical and electrical remedial and upgrade works within their academy schools in Cornwall.

We have successfully carried out heating repairs, BEMS upgrades, fire alarm and ventilation modifications to a number of schools across Cornwall. As part of the project works we also employ and manage the sub-contractors offering our Clients a “one stop shop” for all their M&E needs.

Posted on April 27, 2018 by Focus Technology -

Greenwich Leisure Limited (GLL) has a 25 year operational lease on a number of leisure centres in the South West of England. Many of these incorporate swimming pools with ageing and inefficient equipment at the end of operational life. The Splash Leisure pool at Bude represented a typical case where capital plant was up for replacement. GPJ Consulting Engineers worked closely with GLL to replace key plant and to incorporate new Building Management Controls. The aim was to use proven control algorithms to reduce the gas costs by 30%, the electricity running costs by 20% and to use far less water. This is being achieved by close monitoring and good pool management.

By remodelling the plantroom and by removing dangerous vertical access ladders, the plant room is now safe to access and free space has been created for sports equipment storage. The new pressure jet condensing boilers can now operate at lower flow and return temperatures which in turn allow them to condense all year round. Independent gas fired hot water generators improve redundancy and allow weather compensated and optimised low temperature boiler operation.

A new pool air handling unit has been installed to provide clean filtered air at the optimum humidity and temperature to ensure energy is not wasted.

Cold water storage tanks and booster sets are now no longer needed and they have been removed thus saving on maintenance and cost of bi-annual tank cleaning. GLL managers are now able to remotely monitor Gas, Electricity and Water consumptions on a daily basis.

GLL now have a safe and optimally run facility which enhances the customer experience and reduces the operational and utility cost burden.

Posted on April 27, 2018 by Focus Technology -

GPJ Consulting Engineers were appointed to improve the gravity drainage system at Lowen Ward. The existing system had a history of blockages and overflow problems which was completely unacceptable for a ward accommodating immune-suppressed patients and which required constant attention from the hospitals maintenance department.

A Vacuum Drainage System was proposed to operate independently of the existing Gravity Drainage System and has been successfully installed complete with a complete training package for the sites maintenance staff.

The system incorporates a new suite of sanitary furniture throughout the ward and a new external plant room which accommodates the main vacuum plant. Waste is transported vertically from WC’s, Sinks and Drains directly back to the Vacuum Plant Room through a system of pipework. The waste is then macerated and pumped to the local foul drain.

The project was managed and phased so that parts of the ward could remain in operation as the old system was de-commissioned and the new vacuum drainage system was installed and phased into use.

Drainage system maintenance issues have now decreased substantially with only one critical fault in twelve months of operation (a blocked pump) providing a substantial improvement on the now redundant gravity system.

Posted on April 27, 2018 by Focus Technology -

GPJ Consulting Engineers were Mechanical, Electrical and Public Health Consultants for 2off 7 million pound research facilities in Guildford, Surrey.

The complex M&E installations for the ISO 10 & 11 buildings were designed by GPJ Consulting Engineers who also carried out the project management of both developments. The buildings are highly serviced and had to comply with stringent guidelines for research and laboratory facilities, including CAT 4 Bio Secure Animal Containment. The buildings have to be maintained under a negative pressure regime to ensure the diseases under research do not escape, these are then passed through HEPA filters to remove the finest air particles from the exhaust air.

A full heat recovery system is installed to recover heat from the air supply system and the steam effluent treatment plant forming part of this building. A new 11kVA electrical substation and emergency backup generators formed part of these works.

Posted on April 27, 2018 by Focus Technology -

GPJ Consulting Engineers have a large presence in the Animal Biocontainment Sector and have vast experience of successful new build and refurbishment projects.

Generally laboratories and scientific facilities are heavily serviced, meaning they are heavily reliant on the building services to provide the required level of containment and to monitor the internal conditions and provide alarms when a potential containment breach occurs.

The level of containment is directly dictated by the pathogen under investigation or expected at the facility. The classification of the Pathogens are as dictated by the Department for Environment, Food and Rural Affars (DEFRA), Specified Animal Pathogens Order (SAPO).

Our past projects include:

- Containment Level (CL) 4 facility design and build to study livestock disease

- CL3 facilities refurbishment to study animal, bird and aquatic disease

- Modular Post Mortem facilities (CL2)

- High Security Unit (HSU) refurbishment (CL3)

- Peer review of existing facilities in the UK, Montenegro, Armenia and Poland

Systems design to include:

- Pressure and Ventilation regimes including heating, cooling, heat recovery and filtering (HEPA)

- Hot and Cold Water Systems with dosing and bio safe operation

- Negative pressure drainage design with integrity monitoring

- Effluent Treatment Plant (Thermo, Thermo-Chem and manual dosing)

- Security Systems for science, monitoring and restricted access

- Emergency and panic Alarms

- Standby Generators and Uninterruptible Power Supplies (UPS)

- Environment and Systems monitoring Control Systems

- Decontamination of material and bodies interacting with scientific spaces

- Process Flow Analysis for any interaction with the facility (staff, waste, pathogen, vehicles etc)

- Alkaline Hydrolysis (AD) Plant

- Automated Fumigation Systems

- Consultation against current Advisory Committee on Dangerous Pathogens (ACDP) guidelines and bio-containment best practice.

Posted on April 27, 2018 by Focus Technology -

GPJ Consulting Engineers were commissioned by the University to design a new drainage system to support their large and small animal post mortem rooms within their globally respected veterinary school.

Due to site restrictions a new pumped contained drainage scheme was selected as the most appropriate for the facilities.

The drainage scheme consisted of a series of electrofusion welded prefabricated pipe sections running to bespoke pumping and valve chambers. From the chambers approximately 400m of buried pipes ran across the site to a gravity outfall to mains drainage.

The system is fully automated and ensures compliance with BBSRC and SAPO regulations.

New internal “low snag” drainage gullies were designed to fit within their existing gully pots to improve water flow and minimise blockages.

As part of the works the existing drainage systems within the PM suites were modified to operate under slight negative pressure to minimise odours from the open gullies.

Posted on April 27, 2018 by Focus Technology -

GPJ Consulting Engineers were commissioned by a Private Client to provide heating, hot water and ventilation designs for their private dwelling.

Heating was designed to utilise a ground source heat pump using a new manmade lake as the heat source. GPJ Consulting Engineers carried out a ground survey to establish the optimum location and size for the lake. Automated sluice valves were integrated into decorative weirs and channels to control the flow of water through the lake.

Pipe coils were sunk within the lake to capture the heat. From these coils buried flow and return pipes run to the plant room where they connected to the heat pump.

This heat was then utilised for underfloor heating. Radiators and pre heating the domestic hot water.

Posted on April 25, 2018 by Focus Technology -

GPJ Consulting Engineers have been employed by Truro Cathedral since 2002. Over the years we have designed new boiler installations, electrical works and ventilation upgrades to the main Cathedral building.

With a proven track record we were employed to continue our M&E design role for the refurbishment of the Old Cathedral School building. The building having previously been used as a council office was in need of a major refurbishment to become a business, cultural arts centre.

New heating, lighting, small power, domestic services, alarms, communications and utilities were designed to suit the buildings new role. Our engineers supervised the installation of the systems throughout the construction period.